The field of industrial maintenance has witnessed a transformative shift with the integration of acoustic imaging technology into fault diagnosis systems. Unlike traditional methods that rely heavily on visual inspections or manual testing, acoustic imaging offers a non-invasive, high-resolution approach to identifying mechanical and electrical anomalies. By capturing and analyzing sound waves emitted by equipment, this technology enables engineers to pinpoint issues with unprecedented accuracy, often before they escalate into costly failures.

One of the most significant advantages of acoustic imaging is its ability to detect faults in real-time, even in noisy environments. Modern systems leverage advanced algorithms to filter out background noise, isolating the specific frequencies associated with malfunctions. This capability is particularly valuable in industries such as manufacturing, energy, and transportation, where early detection of faults can prevent downtime and enhance operational efficiency. The precision of these systems has reached a level where even minor irregularities, such as loose components or early-stage bearing wear, can be identified with remarkable clarity.

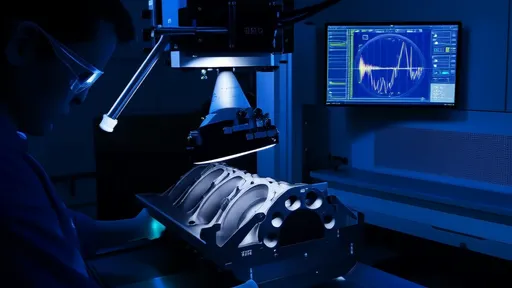

The accuracy of acoustic imaging fault diagnosis systems hinges on several factors, including sensor quality, data processing techniques, and the integration of machine learning. High-resolution microphones and ultrasonic sensors capture sound waves across a broad spectrum, while sophisticated software analyzes these signals to generate detailed visual representations of potential issues. Machine learning algorithms further refine this process by learning from historical data, improving diagnostic accuracy over time. As a result, these systems are becoming indispensable tools for predictive maintenance strategies.

Recent case studies highlight the practical benefits of acoustic imaging in real-world applications. For instance, in the wind energy sector, turbines are subjected to constant stress and environmental wear. Acoustic imaging systems have been deployed to monitor blade conditions, detecting cracks or imbalances that could lead to catastrophic failures. Similarly, in the automotive industry, manufacturers use this technology to assess the integrity of electric vehicle batteries, identifying thermal anomalies that might indicate potential safety hazards. These examples underscore the versatility and reliability of acoustic imaging in diverse settings.

Despite its many advantages, the adoption of acoustic imaging for fault diagnosis is not without challenges. Calibration and setup require specialized expertise, and the initial investment in equipment can be substantial. However, as the technology matures and becomes more accessible, these barriers are expected to diminish. Industry experts predict that the next generation of acoustic imaging systems will feature enhanced portability, faster processing speeds, and even greater precision, further solidifying their role in modern maintenance practices.

Looking ahead, the convergence of acoustic imaging with other emerging technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), promises to revolutionize fault diagnosis. IoT-enabled sensors can transmit real-time acoustic data to centralized platforms, enabling remote monitoring and analysis. AI-driven systems, on the other hand, can autonomously diagnose faults and recommend corrective actions, reducing the need for human intervention. This synergy is poised to elevate the standards of industrial maintenance, making processes smarter, faster, and more reliable.

The future of fault diagnosis lies in the continued refinement of acoustic imaging techniques. Researchers are exploring ways to enhance resolution, reduce latency, and expand the range of detectable faults. As these innovations unfold, businesses across sectors will benefit from reduced maintenance costs, improved safety, and prolonged equipment lifespans. Acoustic imaging is not just a tool for today—it is a cornerstone of the next era of industrial diagnostics.

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025