The global IT supply chain has emerged as a critical backbone of modern economies, connecting manufacturers, service providers, and consumers across continents. However, recent disruptions—from geopolitical tensions to pandemics—have exposed vulnerabilities in this intricate network. Building resilience in the IT supply chain is no longer a choice but a necessity for businesses and governments alike. The challenge lies in balancing efficiency with adaptability, ensuring that disruptions don’t cascade into systemic failures.

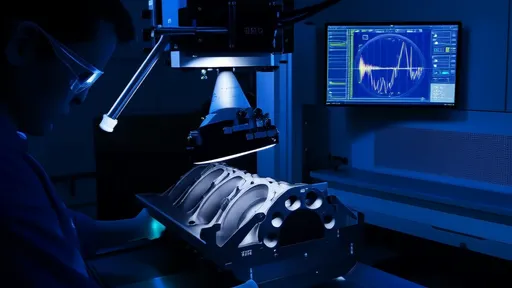

One of the most pressing issues is the concentration of semiconductor production in a handful of regions. Over 90% of advanced chips are manufactured in Taiwan and South Korea, creating a single point of failure for industries ranging from automotive to consumer electronics. When COVID-19 lockdowns hit or trade tensions flared, the ripple effects were felt worldwide. Companies are now reevaluating their reliance on geographically concentrated suppliers, exploring alternatives in Southeast Asia, India, and even reshoring production to North America and Europe.

The role of governments in fostering supply chain resilience cannot be overstated. Policies such as subsidies for local semiconductor fabs or tax incentives for diversifying suppliers are gaining traction. The U.S. CHIPS Act and the European Chips Act are prime examples of legislative efforts to reduce dependency on foreign suppliers. Yet, these initiatives must be carefully calibrated to avoid trade wars or inefficiencies that could arise from overprotectionism. Collaboration between nations, rather than isolation, may hold the key to long-term stability.

Technological innovation is another pillar of resilience. Advances in AI and blockchain are enabling real-time tracking of supply chain disruptions, allowing companies to pivot quickly when bottlenecks emerge. Predictive analytics can forecast shortages before they occur, while digital twins—virtual replicas of physical supply chains—help simulate and mitigate risks. These tools are not just for large corporations; SMEs are increasingly adopting cloud-based solutions to enhance their agility without massive upfront investments.

Cybersecurity remains a blind spot in many supply chain strategies. The 2020 SolarWinds attack demonstrated how a single compromised software update could infiltrate thousands of organizations. As supply chains become more digitally interconnected, the attack surface expands. Regular audits, zero-trust architectures, and mandatory cybersecurity standards for suppliers are becoming essential components of a robust resilience framework. The focus must shift from reactive measures to proactive defense mechanisms.

Talent shortages further complicate resilience efforts. The IT supply chain relies on a skilled workforce capable of managing complex logistics, advanced manufacturing, and cutting-edge R&D. Countries and companies investing in STEM education and vocational training will have a competitive edge. Initiatives like Germany’s dual education system, which combines classroom learning with hands-on apprenticeships, offer a model for bridging the skills gap. Retention strategies, including flexible work arrangements and upskilling programs, are equally critical.

Sustainability is no longer an afterthought in supply chain discussions. Consumers and regulators are demanding greener practices, from reducing e-waste to minimizing carbon footprints in logistics. Circular economy principles—where products are designed for reuse and recycling—are gaining momentum. Companies like Apple have made strides in using recycled materials for their devices, but broader industry-wide standards are needed to scale these efforts. Resilience and sustainability are increasingly seen as two sides of the same coin.

The path forward requires a paradigm shift in how businesses approach their IT supply chains. Traditional just-in-time models prioritized cost savings over redundancy, but the new normal demands a balance between the two. Multi-sourcing, buffer inventories, and regionalized production hubs can provide the flexibility needed to withstand shocks. This transition won’t be easy or cheap, but the cost of inaction—measured in lost revenue, jobs, and innovation—is far greater.

Ultimately, building a resilient global IT supply chain is a collective endeavor. It calls for unprecedented cooperation between private sectors, governments, and international bodies. The lessons from recent crises are clear: fragility comes at a steep price, and resilience is an investment that pays dividends in stability and growth. As the world grows more interconnected, the systems that bind us must be robust enough to endure the uncertainties ahead.

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025

By /Jul 11, 2025