The world of sustainable materials is witnessing a quiet revolution with the emergence of Barkcloth 2.0 – a next-generation iteration of the ancient fabric now supercharged with nanotechnology. This isn’t just another eco-friendly textile; it’s a paradigm shift in how we perceive the strength and versatility of plant-based fibers. Researchers and material scientists are redefining the boundaries of natural materials by embedding nanocellulose structures within traditional barkcloth, resulting in a composite that rivals synthetic fabrics in durability while retaining its biodegradable essence.

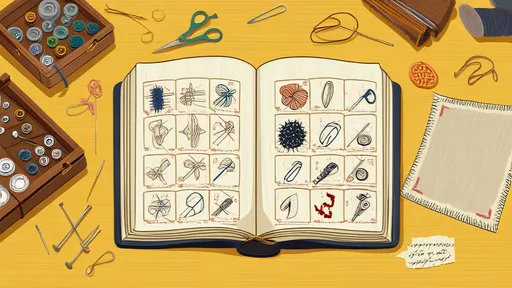

Barkcloth, historically made from the inner bark of trees like the fig or breadfruit, has been used for centuries across tropical regions. Its revival in modern times stems from a growing disillusionment with petroleum-based textiles and a collective push toward circular economies. However, the inherent limitations of natural fibers – susceptibility to moisture, lower tensile strength, and wear over time – have kept them niche. That’s where nanotechnology intervenes. By impregnating the fibrous matrix of barkcloth with nanocrystals extracted from the same plant sources, scientists are creating a self-reinforcing material where every strand gains molecular-level scaffolding.

The process begins with the careful harvesting of tree bark, which undergoes fermentation and beating to create the traditional cloth base. What sets Barkcloth 2.0 apart is the subsequent immersion in a nanocellulose suspension derived from agricultural waste. These nanoparticles, often measuring less than 100 nanometers in width, penetrate deep into the fiber’s microstructure. When cured under controlled conditions, they form a web-like network that bonds with the cellulose present in barkcloth. The result is a fabric that demonstrates a 300% increase in tear resistance compared to untreated barkcloth, while maintaining breathability and flexibility.

Beyond mechanical properties, the nanotechnology infusion bestows unexpected functionalities. The nanocellulose network creates a natural barrier against microbial growth, making the fabric inherently antimicrobial without chemical treatments. This characteristic, combined with the material’s UV resistance observed in preliminary tests, opens doors for medical applications – think biodegradable wound dressings or antimicrobial hospital linens that decompose after use. Fashion designers collaborating on pilot projects report that the enhanced barkcloth drapes similarly to heavy silk yet withstands repeated washing, addressing one of traditional barkcloth’s main drawbacks.

Environmental implications run deep with this innovation. Unlike synthetic nanofibers that risk ecosystem contamination, the plant-derived nanocellulose used here maintains full biocompatibility. At the end of its lifecycle, Barkcloth 2.0 can be composted, with the nanoparticles breaking down harmlessly alongside the organic fibers. Early lifecycle assessments suggest the production process requires 80% less energy than polyester fabric manufacturing, with the added benefit of carbon sequestration from the source trees. Smallholder farmers in Uganda and Indonesia, where barkcloth traditions remain vibrant, are being trained in nanocellulose extraction from crop residues, creating new income streams alongside textile production.

Commercial adoption is already underway, though challenges persist. Scaling the nanotechnology treatment while keeping costs competitive with conventional textiles remains a hurdle. Some manufacturers are experimenting with combining barkcloth with other reinforced natural fibers like hemp or flax to create hybrid materials for specific applications. The automotive industry has shown particular interest, with prototypes of car door panels and trunk linings made from Barkcloth 2.0 composites that are lighter than fiberglass yet meet stringent durability requirements. In architecture, designers are exploring its use as a sustainable alternative to acoustic paneling, leveraging the material’s natural sound-absorbing properties enhanced by the nanocellulose infusion.

Critically, this innovation represents more than a new material – it’s a bridge between ancestral knowledge and cutting-edge science. Indigenous communities involved in barkcloth production are partnering with research institutions, contributing generations of craftsmanship to inform the nanotechnology integration. Their understanding of tree varieties, harvesting seasons, and traditional processing methods proves invaluable in optimizing the enhanced fabric’s performance. Several patents filed around Barkcloth 2.0 explicitly acknowledge these community contributions, setting a precedent for ethical bioeconomy development.

As consumer demand for genuinely sustainable materials grows, Barkcloth 2.0 stands poised to transition from specialty markets to mainstream applications. Its development underscores an important truth in material science: sometimes the most advanced solutions don’t come from creating something entirely new, but from profoundly understanding and augmenting what nature already provides. With ongoing research into optimizing nanoparticle dispersion and exploring additional functional treatments like natural dye compatibility, this ancient-turned-novel fabric is rewriting the narrative of what plant-based materials can achieve.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025