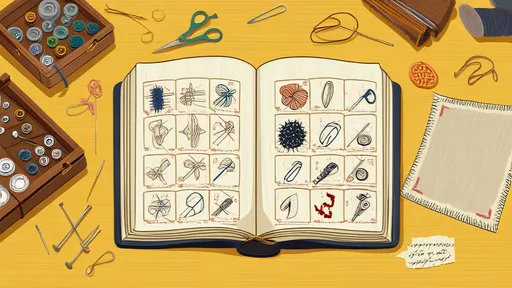

The history of fasteners is a fascinating journey through human ingenuity, mirroring our technological and cultural evolution. From prehistoric bone needles to modern magnetic smart closures, these humble devices have quietly shaped civilizations by holding together everything from clothing to spacecraft. The story of fasteners reveals how humanity has continuously reinvented the way we connect materials - and by extension, how we live.

Ancient Beginnings: Nature's Blueprint

Early humans looked to nature for solutions, fashioning the first fasteners from animal bones, horns, and ivory. Archaeologists have discovered bone needles dating back 50,000 years, some complete with eyelets for threading sinew. These primitive tools allowed Paleolithic people to assemble fitted garments that provided better protection against harsh climates than simple wraps or hides. The invention of sewing marked a cognitive leap - our ancestors weren't just covering their bodies but engineering wearable solutions.

As metalworking emerged around 3000 BCE, copper and bronze pins replaced bone versions. The safety pin's ancestor appeared in Mycenaean Greece around 1500 BCE - a simple wire bent back on itself with a catch plate. These early metal fasteners represented more than practical tools; they became status symbols, with elaborate designs indicating wealth and position. The famous Celtic brooches of the Iron Age, for instance, combined functionality with intricate artistry.

Medieval Innovations: Function Meets Form

The Middle Ages saw fastener technology accelerate alongside armor development. Knights needed secure yet flexible plate armor attachments, leading to sophisticated hinge and clasp systems. These military innovations filtered into civilian clothing as the Renaissance approached. Buttons evolved from simple fabric ties to decorative items, first appearing as functional fasteners in 13th-century Germany. By the 14th century, buttonholes were invented, creating a revolutionary closure system that dominated fashion for centuries.

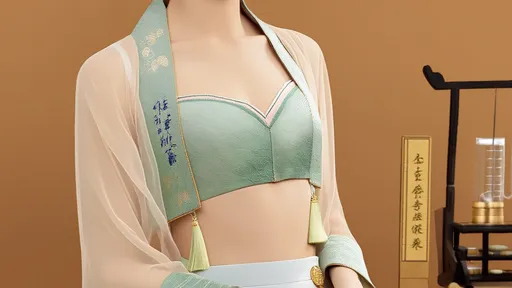

Meanwhile, in Asia, traditional garments used entirely different fastening philosophies. The Chinese developed intricate knot buttons and frog closures, while Japanese kimono relied on obi sashes. These Eastern solutions emphasized flexibility and adjustability, contrasting with Western approaches that prioritized precise fit. The cultural differences in fastening systems reveal how clothing reflects philosophical values - constraint versus flow, structure versus adaptability.

Industrial Revolution: Standardization and Scale

The 19th century transformed fasteners from handcrafted items to mass-produced commodities. Elias Howe's sewing machine (1846) created demand for standardized threads and needles. Meanwhile, the growing ready-to-wear clothing industry needed reliable, inexpensive closures. This spurred the development of machine-made hooks and eyes, snap fasteners, and the modern zipper prototype. Whitcomb Judson's "clasp locker" debuted at the 1893 Chicago World's Fair, though it would take decades to perfect the zipper we know today.

Perhaps the most impactful innovation was the humble rivet. Originally used in shipbuilding and armor, Levi Strauss and Jacob Davis adapted copper rivets for work pants in 1873, creating the first blue jeans. This marriage of industrial fastener and durable fabric birthed an iconic garment that would transcend its working-class origins. The rivet's journey from battleships to back pockets exemplifies how fastener technologies cross-pollinate between industries.

20th Century: Specialization and Space-Age Materials

World War II accelerated fastener innovation, particularly in aviation and military gear. Nylon replaced metal in many applications, reducing weight while resisting corrosion. The war effort also perfected Velcro, though this Swiss invention wouldn't become widespread until the 1960s space program. Suddenly, astronauts were floating in capsules held together by hook-and-loop fasteners, making the technology seem futuristic to earthbound consumers.

Postwar prosperity brought an explosion of specialized fasteners. Plastic molded snaps appeared on children's clothing, while high-performance zippers conquered outdoor gear. Scuba divers needed waterproof closures, skiers required cold-resistant buckles, and astronauts demanded zero-gravity solutions. Each niche market drove innovation, resulting in today's vast array of purpose-built fastening systems. The humble bra alone utilizes dozens of specialized hook-and-eye variations to provide support and comfort.

Digital Age: Smart Fasteners and Biomimicry

Today's cutting-edge fasteners blend materials science with digital intelligence. Shape-memory alloys create self-adjusting closures that tighten or loosen based on temperature. Magnetic systems allow one-handed operation for people with limited mobility. Some high-tech jackets now feature conductive zippers that integrate with wearable electronics. Researchers are even developing "programmable matter" fasteners that can change their properties on command.

Perhaps most intriguing are biomimetic fasteners that imitate nature's solutions. Gecko-inspired adhesives offer strong, residue-free attachment. Mussel-based adhesives work underwater. These bio-inspired designs point toward a future where fasteners seamlessly integrate with materials rather than interrupting them. As wearable technology advances, fasteners are evolving from mechanical connectors to intelligent interfaces that monitor health, adjust fit automatically, or even harvest energy from movement.

The story of fasteners continues unfolding as 3D printing enables customized, on-demand closures and nanotechnology promises molecular-level bonding. What began with a bone needle has grown into a sophisticated field merging engineering, design, and materials science. These unsung heroes of technology still hold our world together - sometimes literally - proving that even the smallest innovations can have outsized impact on human progress.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025