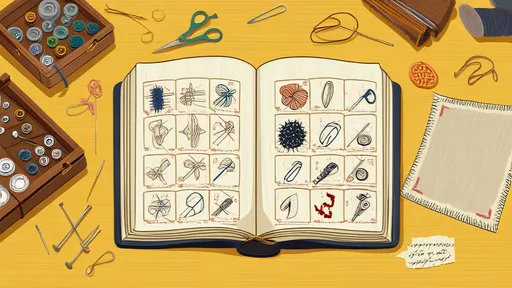

The art of ceramics has long been revered for its delicate beauty and intricate craftsmanship. Among its many techniques, eggshell glazing stands out as a particularly refined method, producing surfaces with a luminous, translucent quality reminiscent of porcelain. Now, this ancient ceramic tradition is finding new life in an unexpected domain: button manufacturing. The transplantation of eggshell glazing techniques onto buttons represents a fascinating convergence of heritage craftsmanship and contemporary design, yielding products that are as visually striking as they are tactilely pleasing.

Eggshell glazing, as the name suggests, involves creating a glaze so thin and delicate that it resembles the fragile surface of an eggshell. Achieving this effect requires meticulous control over glaze composition, firing temperature, and application methods. Ceramic masters have perfected this technique over centuries, producing wares that seem to glow from within. The challenge now lies in adapting these exacting ceramic processes to the much smaller scale of buttons while maintaining the signature ethereal quality of the glaze.

The transition from ceramic vessels to buttons necessitates significant technical adaptations. Where potters work with relatively large surfaces, button artisans must contend with miniature canvases sometimes less than a centimeter in diameter. This scaling down requires reformulating glaze compositions to ensure proper adhesion and finish on smaller substrates. Firing cycles too must be adjusted, as the thermal mass of buttons differs dramatically from that of pottery. Yet these challenges have yielded innovative solutions that are pushing both ceramic and button-making technologies forward.

Material scientists working with button manufacturers have developed specialized clay bodies that can withstand the mechanical stresses inherent in button use while still accepting the delicate eggshell glaze. These composite materials blend traditional ceramic ingredients with modern polymers, creating substrates that marry the aesthetic qualities of porcelain with the durability needed for functional accessories. The resulting buttons possess a unique combination of ceramic elegance and everyday resilience.

Application techniques have undergone similar innovation. Where ceramic glazes might be brushed or sprayed onto pottery, button glazing often employs precision dipping methods or even micro-pipette applications to ensure even coverage on small surfaces. Some artisans have adapted jewelry-making tools to hand-paint intricate designs onto buttons before firing, creating miniature works of art. The firing process itself has been refined to accommodate the smaller pieces, with specialized kilns designed to maintain perfect temperature consistency across thousands of tiny items.

The visual effects achieved through this ceramic-button synthesis are remarkable. Eggshell-glazed buttons capture and refract light in ways that plastic or metal alternatives cannot replicate. They offer a subtle luminosity that changes with the wearer's movement, creating dynamic visual interest. The translucent quality of the glaze allows for layered decorative effects, with underglaze designs showing through the thin ceramic surface. Color possibilities range from delicate pastels to rich, saturated hues, all with that distinctive eggshell glow.

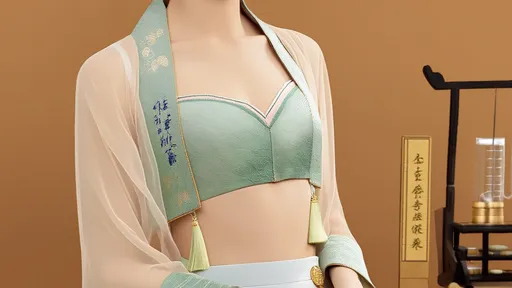

From a design perspective, these ceramic buttons open new creative possibilities. Fashion designers are incorporating them into garments where they serve as subtle yet sophisticated accents. The buttons' ceramic nature makes them particularly suitable for organic, sustainable fashion lines, appealing to environmentally conscious consumers. Jewelry designers too have embraced them, using the glazed buttons as focal points in necklaces, bracelets, and earrings. The marriage of ceramic artistry with wearable design has created a new category of artisanal accessories.

The market response to eggshell-glazed buttons has been enthusiastic. High-end fashion houses have begun specifying them for couture pieces, while crafters appreciate their unique qualities for handmade garments. The buttons have found particular favor in bridal wear, where their delicate appearance complements formal attire. As production techniques continue to refine, these ceramic buttons are moving beyond the luxury market into broader accessibility.

Environmental considerations have played a significant role in the development of ceramic buttons. Unlike plastic alternatives, they offer a biodegradable option at the end of their lifecycle. The glazing process, when properly managed, creates minimal waste, and many manufacturers are implementing closed-loop water systems in their production. This ecological profile makes eggshell-glazed buttons particularly appealing in an era of increasing environmental awareness in the fashion industry.

Looking forward, the fusion of ceramic techniques with button manufacturing suggests exciting possibilities. Researchers are experimenting with glazes that change color with temperature or that incorporate luminescent materials for subtle nighttime visibility. Others are exploring how to integrate smart technology with ceramic buttons, potentially creating functional interfaces that maintain aesthetic appeal. The success of eggshell glazing in buttons may inspire similar cross-pollination between ceramics and other unexpected product categories.

The story of eggshell glazing's migration from ancient ceramic tradition to modern button design exemplifies how traditional crafts can find renewed relevance through innovative application. It demonstrates that even the most time-honored artistic techniques can adapt to contemporary needs without sacrificing their essential character. As consumers increasingly value both artistry and sustainability in products, such syntheses of old and new will likely continue to emerge, blurring the boundaries between functional items and wearable art.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025